Bioreactors

Bioreactor Models

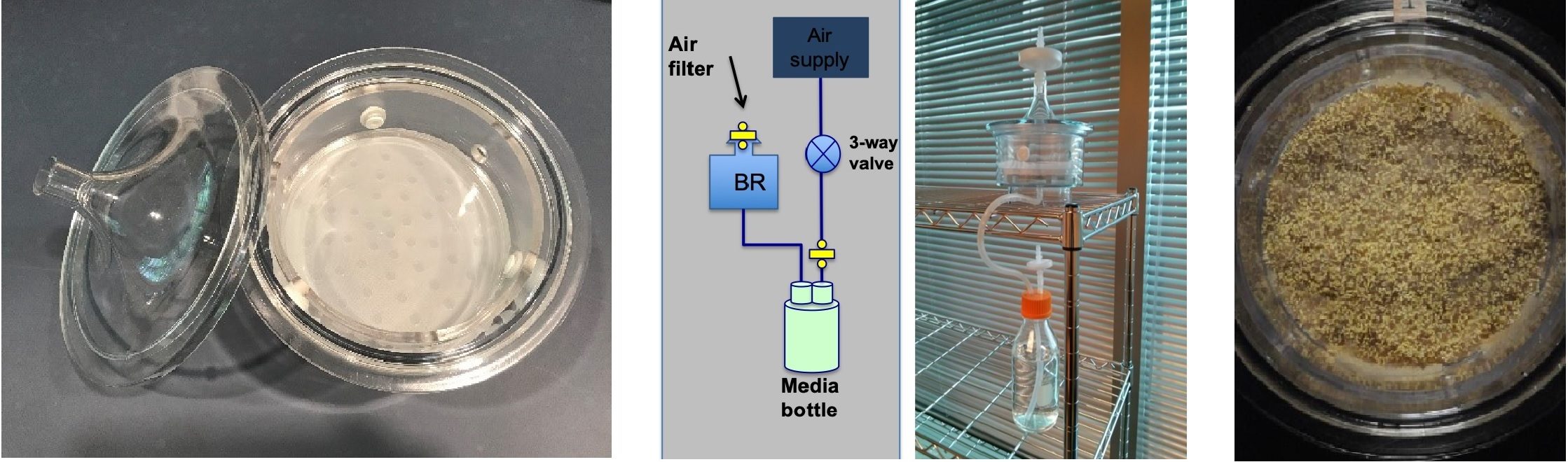

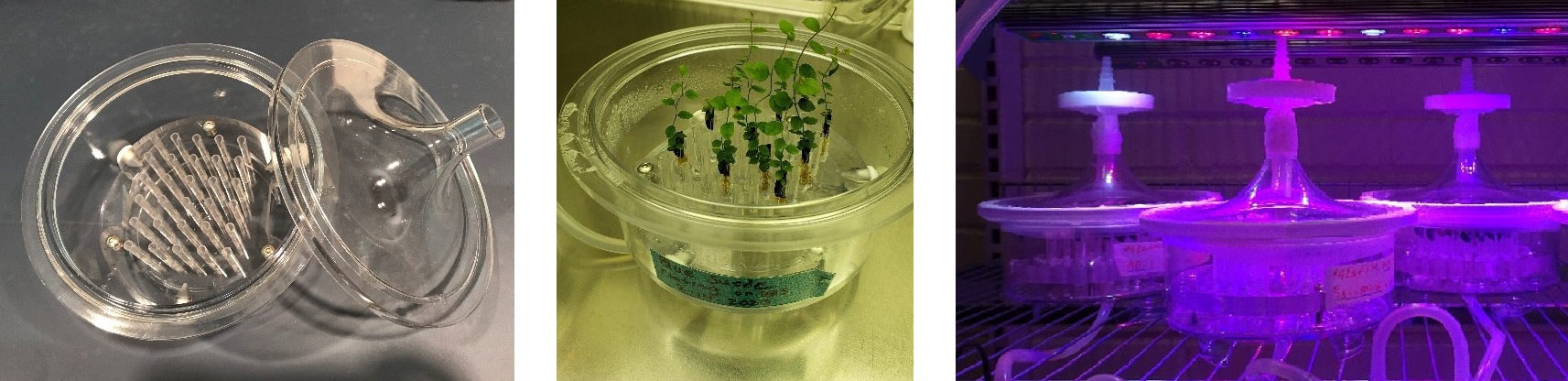

Efficient in vitro production of plant propagules for planting or production of plant metabolites are based on bioreactors1. BSI offers two versions of temporary-immersion bioreactors: BSI Bioreactor Basic is designed for growth and development of plant propagules that do not require directional growth such as callus cultures and cultures of somatic embryos2,3. The BSI V-Germination Bioreactor Plant is designed for plant propagules benefiting from directional growth such as shoots and germination of conifer somatic embryos.

The BSI Bioreactors

- operate by periodic immersion to full immersion controlled by a timer or a centralized computer

- are built from a fully transparent, special bio-compatible polycarbonate plastic with only a few robust parts requiring minimal assembly for use

- are designed for ease of handling, stable sterile operation, can be repeatedly autoclaved without damage to the material and do not scratch easily

BSI Bioreactor Basic

BSI V-Germination Bioreactor Plant

The Basic and V-Germination Plant bioreactors can be scaled-up for large-scale production with centralized control

- Mamun, N.H.A., Egertsdotter, U., Aidun, C.K. 2014. Bioreactor technology for clonal propagation of plants and metabolite production. Frontiers in Biology 10(2) : 177-193

- Businge, E., Trifonova, A., Schneider, C., Rödel, P., Egertsdotter, U. 2017. Evaluation of a New Temporary Immersion Bioreactor System for Micropropagation of Cultivars of Eucalyptus, Birch and Fir. Forests 2017, 8(6), 196; doi:10.3390/f8060196

- Mamun, N.H.A., Aidun, C.K., Egertsdotter, U. 2018. Improved and synchronized maturation of Norway spruce somatic embryos in temporary immersion bioreactors. In Vitro Cell Dev Biol. issue 1 suppl. doi:org/10.1007/s11627-018-9911-4